Spanish island builds ‘giant water battery’ to boost energy security

Story by

Siôn Geschwindt

Gran Canaria is perhaps best known for its sandy beaches, eternal sunshine, and volcanic past. But isolated far from the European mainland, the island relies heavily on imported fossil fuels to power its growing economy — 76% of its electricity comes from burning oil.

In an effort to decarbonise, the government has been investing heavily in renewable energies to harness the island’s abundant wind and solar resources. In 2022, renewables made up 24% of the island’s energy mix, up from just 12% in 2018. But as more renewables come online, the island faces another problem: storage.

Last year, the government invested €400m in the Canary Islands’ first-ever energy storage scheme, to stabilise the grid when the wind isn’t blowing or the sun isn’t shining. This project won’t build battery packs, however, but convert two existing dams into one giant water battery.

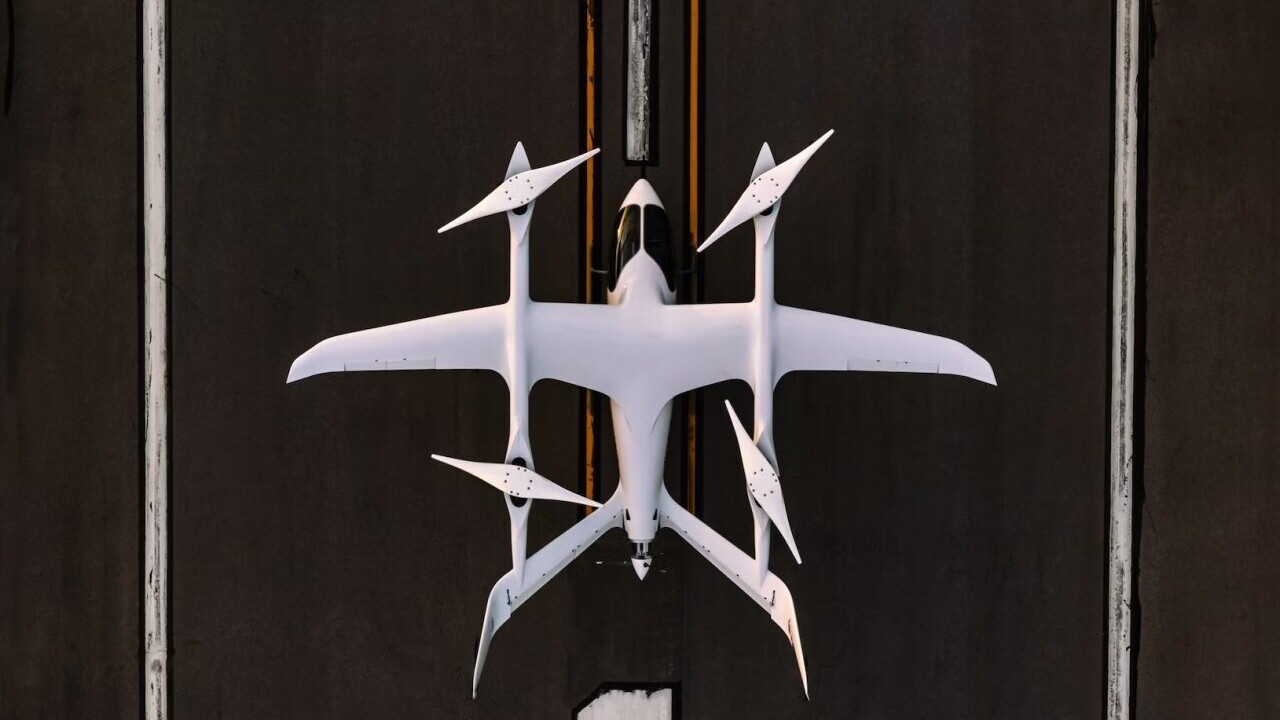

Salto de Chira, as the ‘pumped hydro’ project is known, will pump water from the Soria dam into the Chira dam — which sits at a higher elevation — during periods of low energy demand. During periods of high energy demand, water will be released from Chira, down a tunnel, over a set of turbines, and back into Soria. And the cycle continues.

Pumped hydro is often referred to as a ‘giant water battery’ because it can store and release power on demand. According to the International Energy Agency, it is still the most widely deployed storage technology today, accounting for over 90% of global energy storage capacity.

When it comes online in 2027, the Salto de Chira project is expected to generate up to 200MW of power at times of high demand, equivalent to more than a third of the island’s needs. Last week, Spain’s grid operator Red Eléctrica selected GE Energy to supply the turbines for the plant, in another step forward for the scheme.

According to Red Eléctrica, the project will increase the island’s share of renewables from 24% to 51% and save €122m a year in imported fossil fuel. It is also expected to create more than 4,300 jobs, of which around 3,500 will be on Gran Canaria itself.

President of the Canary Islands, Ángel Víctor Torres, called the project a “great boost” to the archipelago’s ambitions of fully decarbonising its economy by 2040, ten years ahead of the targets set by the EU.

“Energy storage is going to be one of the key elements in the energy transition, both for its contribution to electrification and for its capacity to enable enhanced management of renewable energy, which is especially important in non-interconnected systems such as the islands,” he said.

The Canary Islands has ramped up its decarbonisation efforts significantly in the last five years. The archipelago’s largest renewable energy complex, comprising eight wind farms and 12 solar plants, was inaugurated in 2022 and provides enough energy for around 54,000 households.

Spain’s government and the European Union also recently announced plans to provide €20m in funding to support the development of 65 new solar projects across the Canary Islands by the end of next year. The archipelago is also exploring alternatives such as wave energy, with the first such pilot project launched in February,led by Danish startup Wavepiston.

Key to the success of all these projects, says one study, will be the deployment of sufficient energy storage solutions to stabilise the grid during peak demand, and the construction of sea cables to connect the islands. Pumped hydro seems to be taking care of the former, while the latter is gaining momentum with the first of many power links now under construction to connect Tenerife and La Gomera. The links are expected to decrease the cost of electricity for taxpayers and improve energy security in the archipelago.

As European countries decarbonise their energy systems, adopting energy storage solutions to balance the intermittent supply of renewable energy and increase energy security is becoming increasingly urgent. According to the European Association for Storage of Energy (EASE), the EU will need 200GW of energy storage by the end of the decade and 600GW by 2050.

A new industry coalition launched last week aims to promote sustainable energy storage technologies like batteries, hydrogen, and pumped hydro in order to reach these targets.

“Energy storage is key to building a future-proof, resilient, and decarbonised energy system,” said EU energy chief Kadri Simson at the launch.

Pumped hydro projects can be controversial, however, particularly when they involve dams on rivers that flood land to create new reservoirs and affect ecosystems. But as highlighted in an article published in The Conversation last year, most pumped hydro projects do not require the building of new dams, but the retrofitting of existing ones, as is the case with the Gran Canaria project.

Either way, the IEA’s landmark 2021 Net Zero by 2050 report estimates that an additional 1300GW of hydropower is required if we are to meet the climate targets outlined in the Paris Agreement. This is double the current global capacity.

Get the TNW newsletter

Get the most important tech news in your inbox each week.

Also tagged with

Spanish island builds ‘giant water battery’ to boost energy security Read More »