After borking my Pixel 4a battery, Google borks me, too

The devil is in the details.

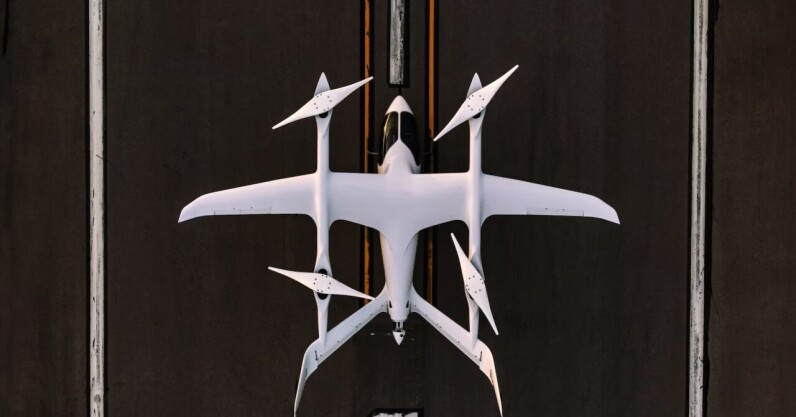

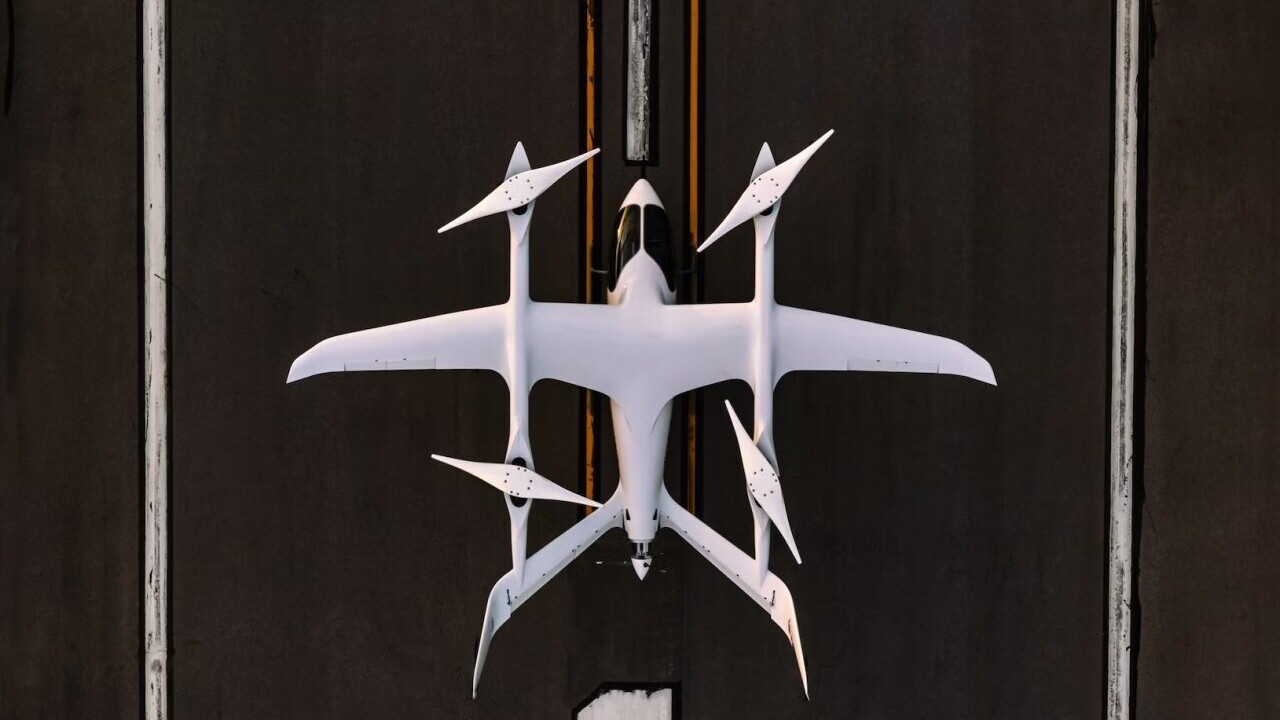

The Pixel 4a. It’s finally here! Credit: Google

It is an immutable law of nature that when you receive a corporate email with a subject line like “Changes coming to your Pixel 4a,” the changes won’t be the sort you like. Indeed, a more honest subject line would usually be: “You’re about to get hosed.”

So I wasn’t surprised, as I read further into this January missive from Google, that an “upcoming software update for your Pixel 4a” would “affect the overall performance and stability of its battery.”

How would my battery be affected? Negatively, of course. “This update will reduce your battery’s runtime and charging performance,” the email said. “To address this, we’re providing some options to consider. “

Our benevolent Google overlords were about to nerf my phone battery—presumably in the interests of “not having it erupt in flames,” though this was never actually made clear—but they recognized the problem, and they were about to provide compensation. This is exactly how these kinds of situations should be handled.

Google offered three options: $50 cash money, a $100 credit to Google’s online store, or a free battery replacement. It seemed fair enough. Yes, not having my phone for a week or two while I shipped it roundtrip to Google could be annoying, but at least the company was directly mitigating the harm it was about to inflict. Indeed, users might actually end up in better shape than before, given the brand-new battery.

So I was feeling relatively sunny toward the giant monopolist when I decided to spring for the 50 simoleons. My thinking was that 1) I didn’t want to lose my phone for a couple of weeks, 2) the update might not be that bad, in which case I’d be ahead by 50 bucks, and 3) I could always put the money towards a battery replacement if assumption No. 2 turned out to be mistaken.

The naïveté of youth!

I selected my $50 “appeasement” through an online form, and two days later, I received an email from Bharath on the Google Support Team.

Bharath wanted me to know that I was eligible for the money and it would soon be in my hands… once I performed a small, almost trivial task: giving some company I had never heard of my name, address, phone number, Social Security number, date of birth, and bank account details.

About that $50…

Google was not, in fact, just “sending” me $50. I had expected, since the problem involved their phones and their update, that the solution would require little or nothing from me. A check or prepaid credit card would arrive in the mail, perhaps, or a drone might deliver a crisp new bill from the sky. I didn’t know and didn’t care, so long as it wasn’t my problem.

But it was my problem. To get the cash, I had to create an account with something called “Payoneer.” This is apparently a reputable payments company, but I had never heard of it, and much about its operations is unclear. For instance, I was given three different ways to sign up depending on whether I 1) “already have a Payoneer account from Google,” 2) “don’t have an account,” or 3) “do have a Payoneer account that was not provided nor activated through Google.”

Say what now?

And though Google promised “no transaction fees,” Payoneer appears to charge an “annual account fee” of $29.95… but only to accounts that receive less than $2,000 through Payoneer in any consecutive 12-month period.

Does this fee apply to me if I sign up through the Google offer? I was directed to Payoneer support with any questions, but the company’s FAQ on the annual account fee doesn’t say.

If the fee does apply to me, do I need to sign up for a Payoneer account, give them all of my most personal financial information, wait the “10 to 18 business days” that Google says it will take to get my money, and then return to Payoneer so that I can cancel my account before racking up some $30 charge a year from now? And I’m supposed to do all this just to get…. fifty bucks? One time?

It was far simpler for me to get a recent hundred-dollar rebate on a washing machine… and they didn’t need my SSN or bank account information.

(Reddit users also report that, if you use the wrong web browser to cancel your Payoneer account, you’re hit with an error that says: “This end point requires that the body of all requests be formatted as JSON.”)

Like Lando Calrissian, I realized that this deal was getting worse all the time.

I planned to write Bharath back to switch my “appeasement,” but then I noticed the fine print: No changes are possible after making a selection.

So—no money for me. On the scale of life’s crises, losing $50 is a minor one, and I resolved to move on, facing the world with a cheerful heart and a clear mind, undistracted by the many small annoyances our high-tech overlords continually strew upon the path.

Then the software update arrived.

A decimation situation

When Google said that the new Pixel 4a update would “reduce your battery’s runtime and charging performance,” it was not kidding. Indeed, the update basically destroyed the battery.

Though my phone was three years old, until January of this year, the battery still held up for all-day usage. The screen was nice, the (smallish) phone size was good, and the device remained plenty fast at all the basic tasks: texting, emails, web browsing, snapping photos. I’m trying to reduce both my consumerism and my e-waste, so I was planning to keep the device for at least another year. And even then, it would make a decent hand-me-down device for my younger kids.

After the update, however, the phone burned through a full battery charge in less than two hours. I could pull up a simple podcast app, start playing an episode, and watch the battery percentage decrement every 45 seconds or so. Using the phone was nearly impossible unless one was near a charging cable at all times.

To recap: My phone was shot, I had to jump through several hoops to get my money, and I couldn’t change my “appeasement” once I realized that it wouldn’t work for me.

Within the space of three days, I went from 1) being mildly annoyed at the prospect of having my phone messed with remotely to 2) accepting that Google was (probably) doing it for my own safety and was committed to making things right to 3) berating Google for ruining my device and then using a hostile, data collecting “appeasement” program to act like it cared. This was probably not the impression Google hoped to leave in people’s minds when issuing the Pixel 4a update.

Removing the Pixel 4a’s battery can be painful, but not as painful as catching fire. Credit: iFixit

Cheap can be quite expensive

The update itself does not appear to be part of some plan to spy on us or to extract revenue but rather to keep people safe. The company tried to remedy the pain with options that, on the surface, felt reasonable, especially given the fact that batteries are well-known as consumable objects that degrade over time. And I’ve had three solid years of service with the 4a, which wasn’t especially expensive to begin with.

That said, I do blame Google in general for the situation. The inflexibility of the approach, the options that aren’t tailored for ease of use in specific countries, the outsourced tech support—these are all hallmarks of today’s global tech behemoths.

It is more efficient, from an algorithmic, employ-as-few-humans-as-possible perspective, to operate “at scale” by choosing global technical solutions over better local options, by choosing outsourced email support, by trying to avoid fraud (and employee time) through preventing program changes, by asking the users to jump through your hoops, by gobbling up ultra-sensitive information because it makes things easier on your end.

While this makes a certain kind of sense, it’s not fun to receive this kind of “efficiency.” When everything goes smoothly, it’s fine—but whenever there’s a problem, or questions arise, these kinds of “efficient, scalable” approaches usually just mean “you’re about to get screwed.”

In the end, Google is willing to pay me $50, but that money comes with its own cost. I’m not willing to pay with my time nor with the risk of my financial information, and I will increasingly turn to companies that offer a better experience, that care more about data privacy, that build with higher-quality components, and that take good care of customers.

No company is perfect, of course, and this approach costs a bit more, which butts up against my powerful urge to get a great deal on everything. I have to keep relearning the old lesson— as I am once again with this Pixel 4a fiasco—that cheap gear is not always the best value in the long run.

After borking my Pixel 4a battery, Google borks me, too Read More »